Description

3M™ Hot Melt Applicators are designed to help improve productivity, lower costs and minimize waste in industrial applications. From high volume to detail work, 3M™ Hot Melt Applicators ensure optimum performance through melt-on-demand or progressive feed technology to meet your production deadlines.

3M™ Hot Melt Applicators can meet your production needs with minimal training:

3M™ Hot Melt Applicator LT

Dispenses low temperature hot melt adhesive at a fixed temperature of 129ºC. Applicator LT is designed for use with low melt 16 mm x 200 mm TC sticks and is capable of dispensing up to 1.2 kilograms of adhesive per hour. The applicator comes with a 2mm tip to meet a wide variety of application needs.

- Lightweight design provides easy handling

- Thumb controlled feeder holds adhesive stick securely and dispenses precisely

- On-demand feed control minimizes waste and dripping

Understanding Hot Melts

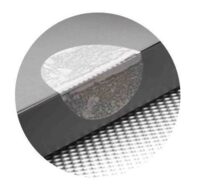

Hot melts extrude as 100% solid liquefied thermoplastic resins to fill gaps and wet surfaces before setting. They often exceed 100 psi shear strength, bond many substrates and are available in a variety of strengths, temperatures and open time/bonding ranges.