On Wednesday, Maxine and I attended a presentation on Compostable Food Packaging. We also had a tour of the Christchurch based Living Earth Organic Processing Plant in Bromley.

Our food scraps and garden waste go into the Green Council Kerbside bins. These bins are collected once a week and taken to the Council’s composting facility in Bromley. Living Earth is Christchurch’s Commercial Composting facility.

All green waste comes in and gets put through a large shredder. This shredder is a rough shredder and the stuff that comes out is larger than tree chipper, this is to ensure more air flow through the pile of waste. More air flow promotes a more efficient composting process.

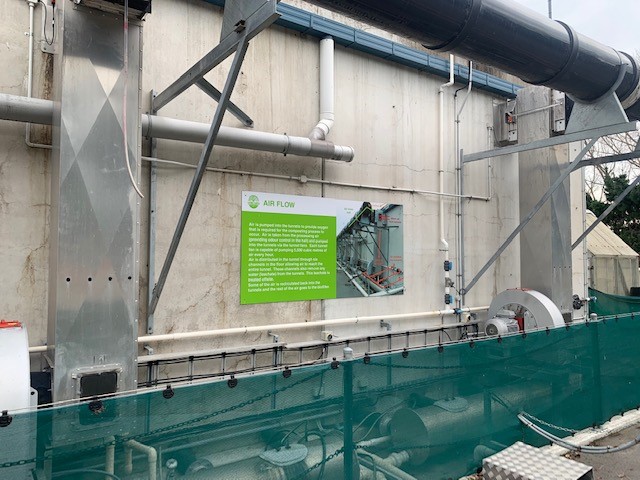

After shredding, the organic waste gets put into long tunnels at high temperatures for a length of time to process. There are 18 tunnels at 6 metres wide x 4.5 metres high x 30 metres long. Each tunnel can hold more than 300 tonnes of material. The tunnels are made of concrete and have air pumped into them to maintain temperature at an optimum level. The air also provides oxygen for the biological process. The optimum temperature for composting is 50 degrees celcius. The air is taken from the processing air and pumped back into the tunnels by large fans. This reduces the odour. The fans can pump 5500 cubic metres of air every hour. The air is distributed into the tunnel through six channels in the floor. This allows for air to reach all of the tunnel. These channels also remove water from the pile of composting material. Some of the air is recycled back into the tunnels and the rest goes to the biofilter.

The temperature of the tunnels is monitored by a system called SCADA. This system measures the temperature to ensure that it is working at an optimal level for composting, weed seed kill and pasteurisation. This removes unwanted and harmful bacteria that may come from bird droppings or dog urine on grass.

The material stays in the tunnels for approximately 11 days in the summer and several weeks in the winter to ensure that the above processes are taking place.

The Biofilter is used to control the odour associated with the composting process. The air that comes out of the tunnels is pumped into the biofilter where the micro organisms that live in the water on the bark, consume the odour particles. This is a naturally occuring biological process and is also monitored at the optimum temperature and moisture levels. The biofilter can hold 1400 cubic metres of bark and can last up to 5 years before it needs changing. Waste water (leachate) drains away from the bottom of the tunnels and mixes with the hot air pumped into the biofilter which condensates from the biofilter and goes to trade waste. This water is storm water quality, which is pretty clean water.

There is a family of peacocks that lives on top of the biofilter and they act as the weedkill system. This waste not part of the plan but it works well. From there, we went up on top of the filters. From the top you can see all the 9.4 hectares of the site. There is usually about 7000 tonnes of finished compost sitting on site at any given time. The nearer piles are the finished compost piles, ready for sale. The bulk of the compost is sold to farmers who use it to add organic material and nutrients to the soil.

The furtherest away piles are the rows of compost that have just come out of the tunnels and are going throug ha maturation process. These piles are turned by the Windrow Turner and water is added.

Once the piles have reached maturity they get screened under the lareg green cover. The cover is to manage dust and odour. There are also window shleter belts that line the site to also capture any dust and odour.

There are also several wind socks on site to show wind direction. If it is too windy they limit operations to minimise the impact on the surrounding area.

I know about this as last night it was blowing a Norwester and I could smell the odour of the compost from my house in Mt Pleasant!

So that’s the tour of the Composting Facility. Living Earth.